Revolutionizing Manufacturing: **China Prototype Injection Molding**

Understanding Prototype Injection Molding

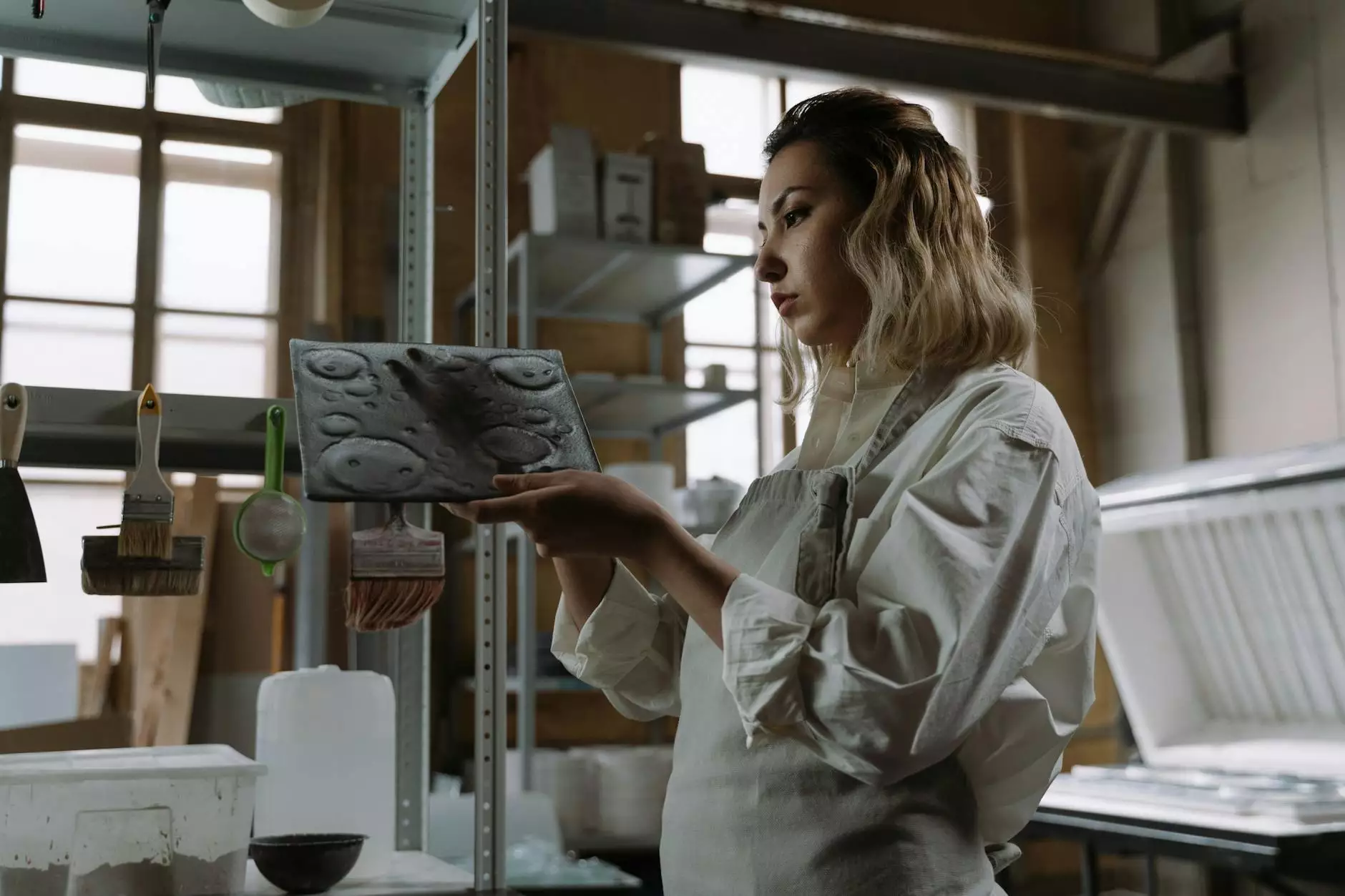

Prototype injection molding is a crucial technique used in the manufacturing sector that enables companies to create product prototypes efficiently and cost-effectively. This process involves injecting molten material (usually plastic) into a mold to create various shapes and designs. By leveraging this advanced technology, manufacturers can quickly shift from concept to tangible product, significantly speeding up the design and testing phases.

The Importance of Prototype Injection Molding in China

China has become a powerhouse in the manufacturing world. The country’s extensive knowledge and investment in injection molding technology set the stage for efficient production and high-quality output. Here are several reasons why China prototype injection molding stands out:

- Skilled Workforce: China boasts a labor force skilled in modern manufacturing techniques, ensuring that every piece is crafted with precision.

- Advanced Technology: The integration of cutting-edge machinery and software enhances production processes and outcomes.

- Cost-efficiency: Low labor and material costs combined with high production capabilities make China an attractive option for businesses worldwide.

Key Benefits of Using China Prototype Injection Molding

Companies considering prototype injection molding in China can expect various advantages:

- Accelerated Development Timeline: Product developers can receive prototypes faster, enabling quicker iterations and reducing time-to-market.

- High Precision and Reproducibility: Injection molding ensures that prototypes are consistent and accurate, essential for product testing and validation.

- Material Variety: From thermoplastics to elastomers, the range of materials available allows for flexibility in design and function.

- Lower Costs for High Volumes: While initial tooling costs might be high, the per-unit cost decreases significantly with larger production runs.

The Process of Prototype Injection Molding

The process of prototype injection molding can be broken down into several steps, each critical for ensuring a successful outcome:

- Mold Design: The first step is designing the mold, which must be precisely crafted to achieve the desired shape and dimensions of the product. This usually involves CAD software for high accuracy.

- Mold Fabrication: Once the design is complete, the mold is fabricated using high-quality metal materials that withstand high pressures and temperatures during the injection process.

- Material Selection: Choosing the right material is essential, as it impacts the prototyping outcome. Factors such as strength, flexibility, and temperature resistance must be considered.

- Injection: The selected material is then heated until it becomes molten and injected into the mold under high pressure.

- Cooling and Ejection: After the molten material fills the mold, it is allowed to cool and solidify before the finished prototype is ejected from the mold.

- Finishing Touches: Finally, any necessary post-processing steps, such as trimming or sanding, are performed to ensure the prototype meets quality standards.

Applications of Prototype Injection Molding in Various Industries

The versatility of prototype injection molding allows it to serve multiple industries effectively. Here are some notable applications:

- Automotive: Prototypes for interior and exterior components, safety features, and electronic housings.

- Healthcare: Development of medical devices, drug delivery systems, and disposable instruments.

- Consumer Electronics: Creating prototypes for gadgets, mobile devices, and household appliances that demand aesthetic and functional excellence.

- Toys and Games: Manufacturing prototypes that are safe and engaging for children while being durable for extensive use.

Challenges in the Prototype Injection Molding Process

While China prototype injection molding offers numerous advantages, several challenges can arise. It’s crucial for businesses to understand these to plan accordingly:

- High Initial Costs: The upfront cost for mold design and fabrication can be significant, though this often pays off in larger production runs.

- Complex Designs: Highly intricate designs may present difficulties in mold fabrication and may require advanced engineering skills.

- Material Limitations: Some materials may be challenging to work with or may not yield the desired properties in the final product.

Best Practices for Prototype Injection Molding

To achieve the best results from China prototype injection molding, companies should follow these best practices:

- Collaborate with Experts: Engage skilled designers and engineers to ensure the mold is designed for manufacturability.

- Prototype Iteration: Use the prototype process not just for final validation but also for iteration. Testing different designs can lead to better end products.

- Choose the Right Partner: Work with reliable manufacturers in China that have a track record of quality and customer satisfaction.

- Testing and Quality Assurance: Implement rigorous testing procedures to validate prototypes before moving to production.

Why Choose DeepMould for Your Prototype Injection Molding Needs

When it comes to China prototype injection molding, DeepMould stands out for several compelling reasons:

- Comprehensive Services: DeepMould offers end-to-end services from initial prototyping to final production, ensuring seamless project management.

- Skilled Engineering Team: Our team comprises experienced professionals who understand the nuances of mold design and manufacturing.

- State-of-the-art Facilities: Equipped with the latest technology, our facilities can tackle projects of various complexities.

- Commitment to Quality: We prioritize quality in all our processes, leveraging strict quality control measures to ensure excellence.

- Flexible Solutions: Whether you need small batch prototypes or larger production runs, we can adapt our services to meet your needs.

Get Started with DeepMould Today

If you are looking to develop high-quality prototypes that can help transform your ideas into reality, DeepMould is here to assist you. With our expertise in China prototype injection molding, we ensure that your manufacturing process is efficient, cost-effective, and aligned with your vision.

Contact us today to learn more about our services and how we can help elevate your manufacturing projects.