Understanding the Role of China Prototype Mold Manufacturers in Modern Manufacturing

The manufacturing industry is a cornerstone of modern economies, driving innovation and efficiency. In this context, China prototype mold manufacturers play an essential role in supplying businesses with the tools and materials necessary to create high-quality products. This article will delve deep into what these manufacturers offer, their significance in the production process, and how to choose the right partner for your business needs.

What Are Prototype Molds?

Prototype molds are temporary molds used to create prototypes of products before mass production. This process is crucial for testing designs, assessing functionality, and evaluating materials. The use of prototype molds significantly reduces the risk of costly errors in the final stages of production. Prototype molds are typically made from materials such as aluminum, steel, or even certain plastics, depending on the intended use and number of prototypes that need to be produced.

The Significance of China in the Global Manufacturing Landscape

China has established itself as a global leader in manufacturing, particularly in the field of mold making. The following factors contribute to this prominence:

- Cost Efficiency: Chinese manufacturers often provide competitive pricing due to lower labor costs and economies of scale.

- Advanced Technology: Many Chinese mold manufacturers invest heavily in technology, ensuring they can deliver high-precision molds.

- Experience: With years of experience in the industry, many Chinese mold manufacturers understand the intricacies of different types of molds.

- Robust Supply Chain: China has a well-established supply chain that allows for rapid production and delivery.

Choosing the Right China Prototype Mold Manufacturer

Selecting the right China prototype mold manufacturer can significantly influence your project's success. Here are some crucial considerations:

1. Assessing Quality Standards

Quality is paramount in mold making. Manufacturers should adhere to international quality standards such as ISO 9001. Certifications and industry compliance are indicators of reliability.

2. Technological Capabilities

Consider the technologies used by the manufacturer. Advanced CNC (Computer Numerical Control) machines and CAD (Computer-Aided Design) software are signs of a modern facility capable of producing intricate designs.

3. Communication and Support

Effective communication is crucial. Ensure that the manufacturer has English-speaking staff and offers support throughout the prototype development process. Strong communication fosters collaboration and understanding, minimizing errors.

4. Turnaround Times

In today’s fast-paced market, speed is of the essence. Evaluate the production timelines provided by different manufacturers to ensure they can meet your deadlines.

5. Customer Reviews and Testimonials

Researching customer feedback can give insight into a manufacturer’s reliability and quality. Look for case studies or testimonials that highlight the experiences of previous clients.

Innovations in Prototype Mold Manufacturing

The industry continues to evolve with many innovative approaches and technologies, making the role of China prototype mold manufacturers even more critical. Below are some of the innovations shaping the future of mold manufacturing:

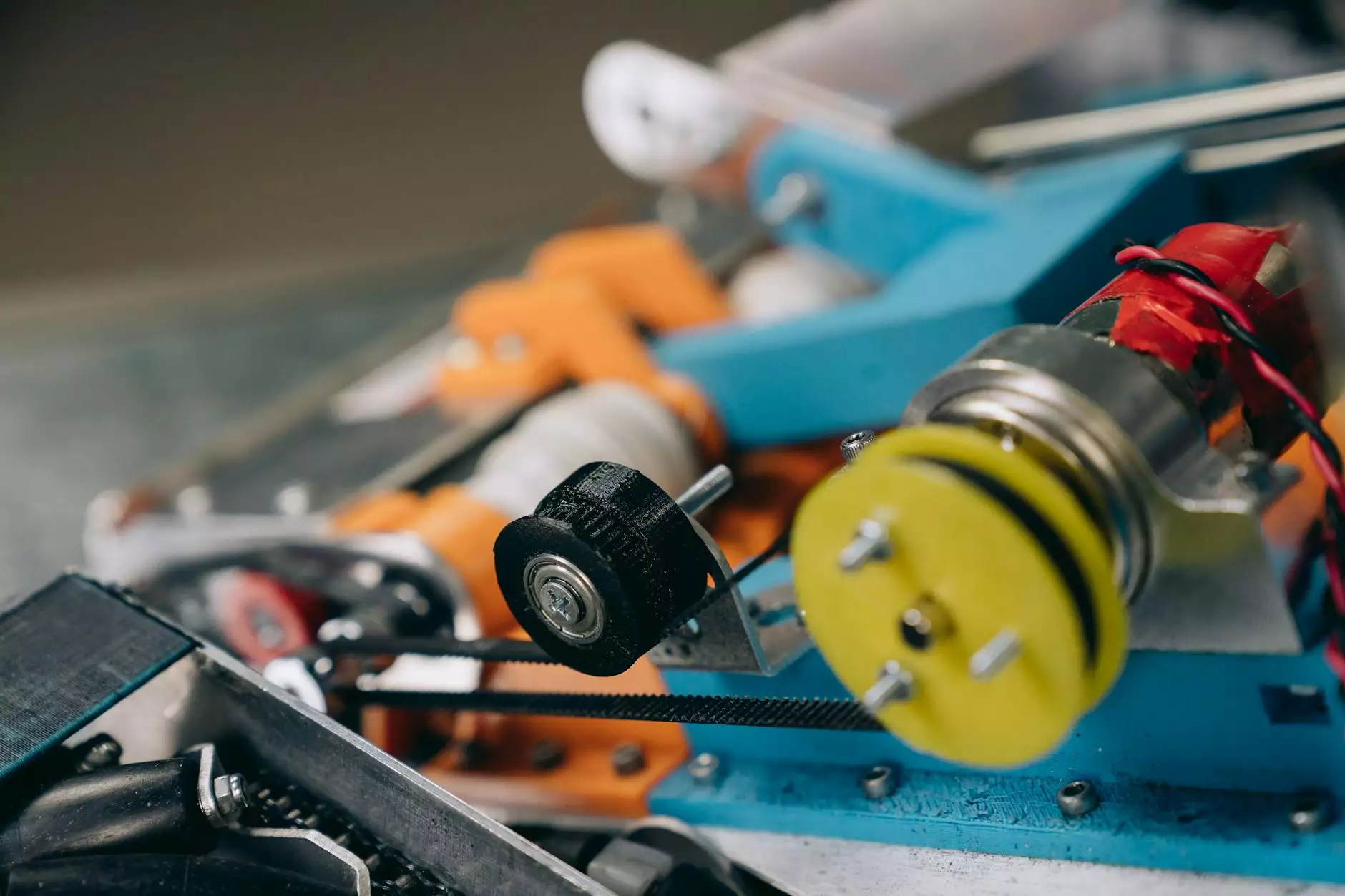

1. 3D Printing

3D printing is revolutionizing the way prototypes are made. It allows manufacturers to create complex shapes with high precision and reduced time. While traditionally molds were made from metals, 3D printing offers a quicker and cheaper alternative for producing prototype molds.

2. Smart Manufacturing

The integration of the Internet of Things (IoT) in manufacturing processes is leading to smarter factories. Sensors and data analytics can optimize production processes, improving efficiency and reducing waste.

3. Materials Advancements

New materials are constantly being developed that offer better durability and performance. For example, composite materials can reduce weight while maintaining strength, which is increasingly important in various industries.

The Process of Prototype Mold Development

Understanding the process of prototype mold development is crucial for effectively collaborating with a mold manufacturer. Here is an overview of the typical workflow:

1. Conceptual Design

The initial step in mold development is to create a conceptual design based on the product requirements. This involves sketching the product and outlining key specifications.

2. CAD Modeling

Using CAD software, engineers will create a digital model of the mold. This model allows for precise calculations and adjustments before moving to the prototype stage.

3. Fabrication of Mold

Once the CAD model is approved, the manufacturer will begin the physical fabrication of the mold using CNC machines or other fabrication methods.

4. Testing and Adjustments

After the mold is produced, it's time to create the initial prototypes. These prototypes will be tested, and any necessary adjustments will be made to the mold to enhance performance or solve any issues.

5. Final Production

Once the prototypes have been tested and approved, production can begin. The mold is used to manufacture the final product in larger quantities.

The Future of Prototype Mold Manufacturing in China

The future of China prototype mold manufacturers looks promising, with several trends expected to shape the landscape:

- Sustainability: There is a growing emphasis on sustainable manufacturing practices. Manufacturers will start incorporating environmentally friendly materials and processes.

- Increased Automation: Automation will continue to reduce labor costs and increase efficiency in the production process.

- Global Partnerships: Chinese manufacturers are likely to form strategic partnerships globally to enhance their capabilities.

Conclusion

In conclusion, China prototype mold manufacturers represent a critical element of the manufacturing industry. Their expertise, technological advancements, and commitment to quality make them invaluable partners for businesses looking to innovate and streamline their production processes. By understanding the role of prototype molds and the factors involved in selecting a manufacturer, businesses can effectively navigate the complexities of modern manufacturing.

Choosing the right manufacturer leads to successful product development and can significantly impact a company’s bottom line. Embracing innovations and maintaining a focus on quality will position businesses to thrive in an increasingly competitive marketplace.

Whether you are in need of metal fabrication services or looking to develop a new product, deepmould.net can provide you with the resources and partnerships necessary to succeed in this dynamic industry.