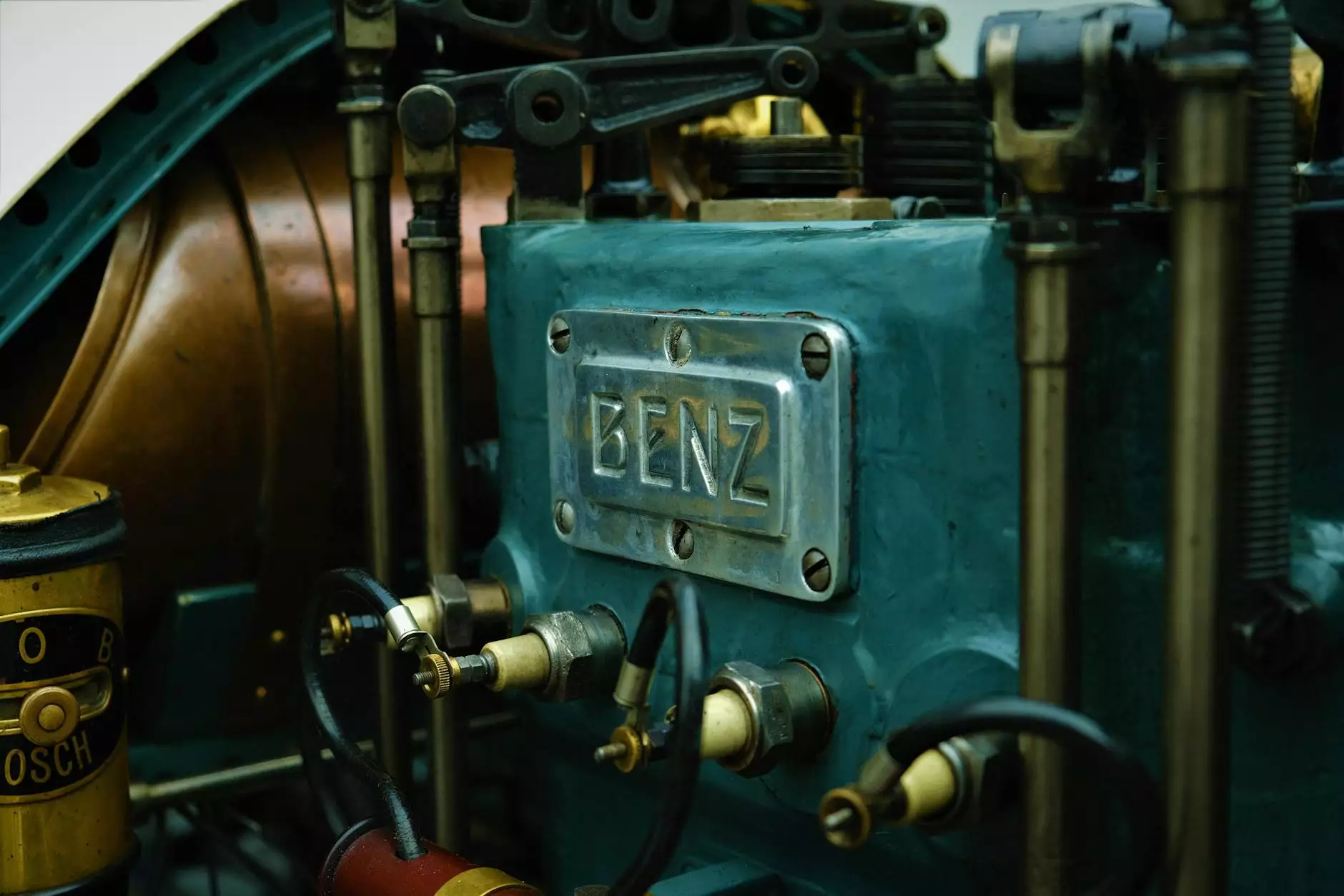

Understanding the Manifold Valve Working Mechanism

The manifold valve working mechanism is a critical component in various systems, especially in industries such as oil and gas, chemical manufacturing, and water treatment. The proper functioning of manifold valves ensures effective management of pressure, flow control, and systematic distribution of fluids. In this article, we will dive deep into the working principles, types, and applications of manifold valves, their advantages, and the integral role they play in enhancing operational efficiency.

What is a Manifold Valve?

A manifold valve is a type of valve system used to control the flow of fluid from multiple sources or to multiple destinations. It typically consists of a series of valves and channels arranged in a coherent structure. This setup allows for the efficient management of various fluids, facilitating easier monitoring and control of pressure and flow rates.

Components of a Manifold Valve

The main components related to the manifold valve working include:

- Body: The main structure that houses the internal elements.

- Valves: Include control and isolation valves which regulate flow through the manifold.

- Ports: Entry and exit points for fluids, strategically placed for optimal performance.

- Pressure Gauges: Instruments used to monitor pressure levels within the manifold.

- Seals and Gaskets: Essential for preventing leaks and maintaining system integrity.

How Does a Manifold Valve Work?

The manifold valve working involves several processes which enable control and routing of fluids:

1. Flow Control

Manifold valves allow for precise flow control from multiple sources. By operating the individual valves, operators can adjust fluid flow to specific applications, ensuring efficiency and preventing system overloads.

2. Pressure Management

Through its configuration, manifold valves help in managing differential pressure across different sections of the system. This ensures stable operation and helps in troubleshooting by isolating parts of the system for maintenance.

3. Monitoring and Regulation

Equipped with pressure gauges, manifold valves enable real-time monitoring of fluid behavior within the system, allowing for timely interventions when necessary.

Types of Manifold Valves

Manifold valves are categorized based on their design and functionality. Some of the common types include:

- Hydraulic Manifold Valves: Used primarily in hydraulic systems for fluid control.

- Pneumatic Manifold Valves: Designed for systems that use gases, offering precise flow control.

- Instrumentation Manifold Valves: Typically used in pressure and temperature measurement applications.

- Electrical Manifold Valves: Integrated with electrical controls for automated operations.

Advantages of Using Manifold Valves

Implementing manifold valves within fluid systems presents numerous benefits:

- Space Efficiency: Reduces the amount of space required for piping and fittings.

- Improved Safety: Enhances leak containment and ensures better pressure management.

- Operational Flexibility: Allows for easy switching between different flow paths and sources.

- Cost Efficiency: Minimizes installation costs and simplifies maintenance processes.

Applications of Manifold Valves

Manifold valves find applications across various sectors:

1. Oil and Gas Industry

In the oil and gas sector, manifold valves are integral for controlling the flow of oil and natural gas during extraction and refining processes.

2. Chemical Processing

In chemical manufacturing, controlling the flow of reagents is critical. Manifold valves help automate and streamline these processes.

3. Water Treatment Plants

Manifold valves are essential in water treatment facilities, allowing operators to maintain optimal flow rates and pressure levels during the purification process.

4. Power Generation

Used within power plants, manifold valves play a crucial role in managing steam and gas flows to ensure efficient power generation.

Installation and Maintenance of Manifold Valves

Proper installation and maintenance of manifold valves are vital for ensuring their long-term effectiveness and reliability:

Installation Guidelines

For successful installation, consider the following:

- Ensure that the manifold is oriented correctly according to the flow requirements.

- Utilize appropriate tools and fittings to connect the manifold to the piping system.

- Conduct pressure tests to ensure there are no leaks after installation.

Maintenance Tips

Regular maintenance checks can enhance the lifespan of manifold valves:

- Inspect seals and gaskets for wear and replace them as needed.

- Monitor pressure levels and flow rates regularly for any abnormalities.

- Ensure that all valves operate smoothly without obstructions.

Conclusion

Understanding the manifold valve working mechanism is essential for professionals in fluid management across various industries. By comprehending how these valves operate, their types, advantages, and applications, businesses can leverage their functionalities to improve operational processes significantly. At TechTubes.in, we specialize in providing high-quality manifold valves and related products that meet your operational needs. Empower your systems with efficient manifold valves and enhance your fluid management capabilities today!

Frequently Asked Questions (FAQs) about Manifold Valves

What are manifold valves used for?

Manifold valves are primarily used to control the flow of fluids in various industrial applications, providing a centralized solution for managing multiple flow paths effectively.

How do you troubleshoot manifold valves?

Troubleshooting manifold valves generally involves checking for leaks, monitoring pressure gauges, and ensuring all valves function properly without blockages.

Are manifold valves suitable for high-pressure applications?

Yes, manifold valves are designed to handle high-pressure conditions; however, selecting the right material and design for the specific application is crucial.

Can manifold valves be automated?

Yes, many manifold valves are compatible with electrical or automated systems that use sensors and controllers to manage fluid flow efficiently.

Where can I buy high-quality manifold valves?

High-quality manifold valves can be purchased from reliable suppliers such as TechTubes.in, which offer a wide variety of fittings and valves suitable for various applications.